FMCG Rejected Products Shredder Destroyer

FMCG Rejected Products Shredder Destroyer Specification

- Frequency

- 50 Hz

- Sheet Capacity

- Multi-layer / Sheet with bulk load

- Application

- Destruction of FMCG Rejected and Expired Products

- Motor Power

- 7.5 HP

- Capacity

- 100 to 300 kg/hr

- Color

- Industrial Grey/Blue Finish

- Noise Level

- < 70 dB

- Control System

- PLC based control panel

- Processing Type

- Shredding/Destroying

- Automatic Grade

- Automatic

- Voltage

- 415 V

- Material

- Mild Steel & Alloy Steel Blades

- Thickness

- Up to 10 mm

- Weight

- Approx 600 - 1200 kg (depending on model)

- Size

- Customized (Varies as per requirement)

- Feeding System

- Conveyor belt/manual feed

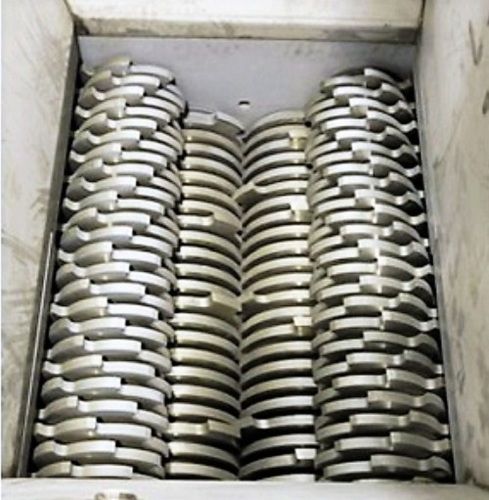

- Blade Type

- Hardened Alloy Steel Rotary & Fixed Blades

- Maintenance

- Low, with easy blade replacement

- Mobility

- Wheeled base for easy movement

- Power Source

- Electric

- Discharge System

- Conveyor or collection bin

- Shred Chamber Size

- 400 x 500 mm / 600 x 800 mm (as per model)

- Power Consumption

- 7.5 kW approx

- Suitable for

- Bottled Goods, Cartons, Tubes, Sachets, Pouches etc.

- Operating Temperature

- Ambient

- Safety Features

- Emergency stop, overload protection, interlock system

FMCG Rejected Products Shredder Destroyer Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- EC

About FMCG Rejected Products Shredder Destroyer

A very reputed company in INDIA came to SHREDALL for a solution to destroy their rejected products and wanted a separator unit also with it, We were able to provide a successful solution to handling, destroying and disposing the rejected FMCG products, having vast experience and a range of reliable shredder machines, the destroying was handled smoothly and fast as per government norms which is crucial.

Our SHREDALL PRIVATE LIMITED company specializes in manufacturing top-of-the-line shredders that ensure efficient and secure destruction of rejected FMCG products in India.

We take pride in our commitment to quality, offering the best high-quality shredders that are unmatched in the market. With our products, you can trust that your rejected FMCG items will be properly disposed of without any risk of them re-entering the market.

Our shredders are designed to meet the highest standards and provide unbeatable performance. We ship worldwide, ensuring that businesses everywhere have access to our superior products for handling rejected FMCG items effectively.

The Basics of FMCG Rejected Products Shredder Destroyer

Crafted with precision and purpose, the FMCG rejected products shredder destroyer stands as a beacon of efficiency in the realm of organic waste management. Its design is tailored to handle the diverse array of materials that constitute rejected FMCG products, including food items, bioplastics, and compostable packaging.

Key Features

We Shredders we are manufacturers of Many Types of Shredders,

-

Multi-stage Shredding Mechanism: Equipped with a series of cutting blades and crushing chambers, the shredder destroyer ensures thorough fragmentation of organic waste, leaving no room for reconstitution.

-

Integrated Sorting System: Advanced sensors and sorting mechanisms enable the shredder destroyer to differentiate between organic and non-organic materials, ensuring that only suitable waste enters the shredding process.

-

Energy Recovery Systems: By harnessing the thermal energy generated during shredding, the machine facilitates energy recovery, minimizing its environmental footprint and promoting sustainable operations.

Shredding Material

The deployment of the FMCG rejected products shredder destroyer heralds a new era of environmental responsibility within the FMCG industry.

Shredding Machine Type

The Shredder Machine is a double shaft cross-cut type, which means it can shred Rejected Products materials into small, manageable pieces for further processing and fast degradation.

Usage/Application

The machine is specifically designed for shredding organic waste in the markets or societies etc. making it a perfect tool for waste management companies handling municipal contracts, restaurants, hotels, and other establishments that deal with a large volume of organic waste.

Capacity

With shredder from 100 kgs/hr to 1000 kgs/hr , the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The Double Shaft Organic Waste Shredder Machine is designed to offer high performance consistently. It is also easy to install and requires minimal maintenance, making it a cost-effective choice for businesses.

Moreover, the installation is done at the customer's premises if required, adding more value to your purchase.

Product Description

The deployment of the FMCG rejected products shredder destroyer heralds a new era of environmental responsibility within the FMCG industry. By efficiently managing organic waste, the machine mitigates the environmental impact of rejection, reducing landfill usage, and curbing greenhouse gas emissions.

Contact Us

We are here to assist you. Feel free to contact us:

-

Email: info@shredall.in

-

+91 9820020754

Conclusion

In the FMCG world, rejected products aren't seen as failures but as steps toward getting better. The FMCG rejected products shredder destroyer quietly handles these rejected items, making sure they're disposed of properly while respecting brand confidentiality and being eco-friendly.

As new ideas come and go, the shredder remains on guard, making sure that even when things don't work out, brands and the environment are still respected and protected.

Advanced Shredding Technology

This shredder destroyer incorporates state-of-the-art rotary and fixed alloy steel blades, ensuring efficient and consistent destruction of a variety of FMCG products. With a customizable chamber, it accommodates various product sizes and materials, streamlining the disposal of rejected or expired items.

Comprehensive Safety Measures

User safety is paramount, supported by emergency stop functions, overload protection, and an interlock system. These features help prevent operational hazards, making the process secure for operators during routine use or maintenance activities.

Flexible Feeding and Discharge Systems

Choose between conveyor belt or manual feeding for enhanced workflow adaptability. The discharge can be managed via a conveyor or a collection bin, offering flexibility according to production set-up and product type for seamless waste management integration.

FAQ's of FMCG Rejected Products Shredder Destroyer:

Q: How does the shredder destroyer process rejected FMCG products?

A: The shredder destroyer uses rotary and fixed hardened alloy steel blades within a robust chamber to shred and destroy various rejected or expired products like bottles, cartons, sachets, and tubes. Materials are fed via conveyor belt or manually, and shredded output is discharged through a conveyor or collection bin.Q: What types of materials or products can be shredded?

A: This machine is suitable for a range of FMCG products including bottled goods, cartons, tubes, sachets, and pouches. It accommodates multi-layer and bulk sheet materials with thickness up to 10 mm, effectively managing different packaging and product types.Q: When is the best time to use this shredder in the product life cycle?

A: It is ideal for use during the disposal or destruction phase of the product life cycle, particularly when handling rejected batches, expired stock, or products returned from the market that require secure destruction to prevent misuse.Q: Where is the FMCG Rejected Products Shredder typically installed?

A: These shredders are commonly installed within manufacturing plants, warehouses, or distribution centers across FMCG companies in India, ensuring compliance with waste management and product destruction regulations.Q: What are the operational safety features included?

A: The shredder is equipped with an emergency stop button, overload protection, and an interlock system that prevent accidental startup during maintenance or when any chamber door is open, ensuring operator safety.Q: How is routine maintenance managed for the machine?

A: Routine maintenance is minimal, thanks to its robust design. Blade replacement is straightforward, and regular checks for motor functioning and safety systems are recommended to maintain optimal performance.Q: What are the main benefits of using this shredder destroyer for FMCG waste?

A: This shredder ensures efficient and secure product destruction, prevents potential misuse of rejected goods, supports regulatory compliance, offers operational flexibility, and features user-friendly maintenance and high mobility within the plant.

Price 300000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Shredder Machine Category

Rafia bag shredder

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 400500 kg/hr

Processing Type : Shredding

Control System : PLC Based

Voltage : 415 V

Military Waste Shredder

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 1000 Kg/hr

Processing Type : Industrial doubleshaft

Control System : Available

Voltage : 440 Volt (v)

4 shaft shredder Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 1000 Kg/hr

Processing Type : Four Shaft

Control System : Yes

Voltage : 440 Volt (v)

Garbage Shredder

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : 500 Kg/hr

Processing Type : Double Shaft

Control System : Available

Voltage : 440 Volt (v)

GST : 27ABKCS4515J1Z1

Send Inquiry

Send Inquiry Send SMS

Send SMS