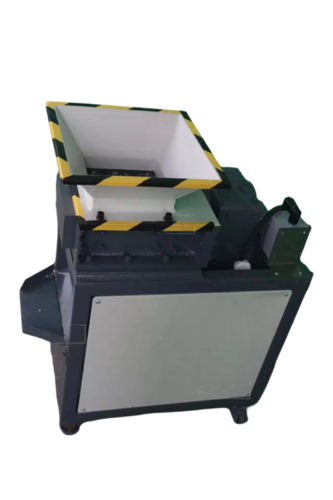

Double shaft Plastic scrap crusher Machine

Double shaft Plastic scrap crusher Machine Specification

- Material

- Mild Steel

- Processing Type

- Crushing & Shredding

- Application

- Plastic waste recycling, PET bottle crushing, plastic scrap processing

- Color

- Industrial Grey & Blue

- Thickness

- Up to 12 mm

- Weight

- 1900 kg

- Voltage

- 380V

- Sheet Capacity

- Up to 25 sheets

- Control System

- PLC controlled

- Frequency

- 50 Hz

- Motor Power

- 15 kW (per shaft)

- Automatic Grade

- Automatic

- Capacity

- 1000 kg/h

- Size

- 1800 x 1250 x 1600 mm

- Noise Level

- 80 dB

- Lubrication System

- Automatic / Manual

- Blade Type

- Hexagonal/Serrated Twin Shaft

- Hopper Size

- Customized as per requirement

- Operating Temperature

- -10C to 50C

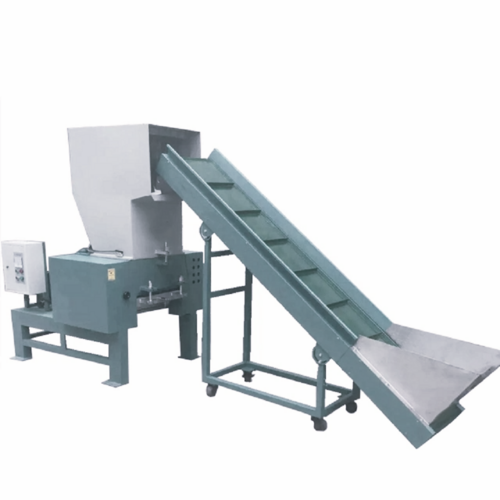

- Feeding Type

- Manual / Conveyor Feeding

- Service Support

- On-site & Remote Support Available

- Discharge Option

- Conveyor / Bin Collect

- Rotor Speed

- 18-25 RPM

- Cutting Chamber Size

- 800 x 600 mm

- Safety Features

- Emergency Stop, Overload Protection

- Drive Type

- Double Drive Electric Motor

- Blade Material

- High alloy steel, wear resistant

- Output Size

- 20 mm to 80 mm (Adjustable)

- Mobility

- Stationary Heavy Base Feet

Double shaft Plastic scrap crusher Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Certifications

- CE

About Double shaft Plastic scrap crusher Machine

SHREDALL Double Shaft Plastic Scrap Crusher Machine, is of very good quality as reliability is paramount for us. At SHREDALL, we take pride in offering top-of-the-line plastic scrap recycling machines at unbeatable prices.

Our commitment to using high-quality materials ensures that our products are durable and efficient and good for high production.

What sets us apart is not just the quality of our machines but also the full support we provide to our customers. From assistance with installation to troubleshooting, we are here every step of the way. Additionally, our warranty gives you peace of mind knowing that your investment is protected.

Whether you are located in India or anywhere else worldwide, weve got you covered. Our efficient shipping services ensure that your Double Shaft Plastic Scrap Crusher Machine reaches you promptly and securely. Trust SHREDALL for all your plastic scrap crushing needs - we deliver on quality, affordability, and service excellence.

The Working Double shaft Plastic Scarp Shredder

The working principle of a SHREDALL double shaft plastic scrap crusher machine involves two counter-rotating shafts fitted with sharp blades or cutters. Plastic scrap is fed into the machine through a hopper and falls between the rotating shafts. As the shafts rotate, the blades or cutters shred the plastic into smaller pieces. The high-speed rotation and cutting action of the blades efficiently reduce the plastic waste into smaller particles. The shredded plastic is then collected for further processing or recycling. The dual shaft design ensures thorough shredding and enables the machine to handle a wide range of plastic materials effectively.

Key Features

-

Dual Shaft Design: Two counter-rotating shafts with sharp blades for thorough shredding.

-

High Efficiency: Rapid shredding of various plastic materials for maximum productivity.

-

Versatility: Suitable for shredding plastic bottles, containers, packaging, and sheets.

-

Durable Construction: Robust materials ensure long-term reliability.

-

Safety Features: Includes mechanisms to protect operators during operation.

-

Easy Maintenance: Designed for simple access to components, reducing downtime.

Shredding Material

The double shaft plastic scrap crusher machine is proficient in shredding a broad spectrum of plastic materials. These include plastic bottles, containers, packaging, sheets, pipes, drums, toys, automotive parts, electronic components, and household items. Through shredding, these materials are reduced into smaller pieces or flakes, rendering them suitable for recycling into new products or subsequent processing within plastic recycling endeavors.

Shredding Machine Type

The double shaft plastic scrap crusher machine is a type of shredding machine used for processing plastic waste. It is equipped with two counter-rotating shafts fitted with sharp blades or cutters that efficiently shred plastic materials into smaller pieces or flakes. This type of shredding machine is versatile, durable, and suitable for various plastic recycling applications, making it an essential tool in combating plastic pollution and promoting environmental sustainability.

Usage/Application

The double shaft plastic scrap crusher machine is used in recycling facilities, manufacturing plants, waste management centers, and environmental initiatives to efficiently process plastic waste into smaller pieces or flakes for recycling. It also finds applications in research and development for studying plastic recycling processes.

Capacity

With a shredder from 500 kgs/hr to 1000 kgs/hr , the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the countrys manufacturing prowess.

High Performance and Easy Installation

Our double shaft plastic scrap crusher machine offers high performance and easy installation, ensuring efficient plastic waste processing with minimal hassle. With its robust design and sharp blades, it efficiently shreds various types of plastic materials, including bottles, containers, packaging, and more. Plus, its user-friendly installation process means you can start recycling plastic waste quickly and effortlessly, making it an ideal choice for businesses, recycling facilities, and environmental initiatives seeking reliable and easy-to-use equipment.

Product Description

SHREDALL double shaft plastic scrap crusher machine is a high-performance solution for efficiently shredding various types of plastic waste, including bottles, containers, packaging, and more. Its robust design and sharp blades ensure thorough shredding, while its easy installation process makes it a convenient choice for businesses, recycling facilities, and environmental initiatives. Start recycling plastic waste quickly and effortlessly with our reliable and user-friendly equipment.

Contact Us

We are here to assist you. Feel free to contact us:

-

Email: info@shredall.in

-

+91 9820020754

Conclusion

SHREDALL Double shaft plastic scrap crusher machine offers a comprehensive solution for processing plastic waste efficiently and effectively. With its high performance, robust design, and user-friendly installation process, it is an ideal choice for businesses, recycling facilities, and environmental initiatives looking to tackle plastic pollution and promote sustainability. Invest in our equipment to streamline your plastic recycling efforts and contribute to a cleaner, greener future.

Precision Engineering for Reliable Crushing

Equipped with high alloy steel blades and a twin-shaft design, this crusher ensures efficient shredding of diverse plastic waste materials, including up to 25 sheets of plastic. The adjustable output and PLC-controlled system deliver consistent, high-capacity performance, making it ideal for manufacturers, recyclers, and plastic processors.

User-Friendly Operation and Safety

The machine supports both manual and conveyor feeding, offering flexibility in operational workflows. Advanced safety features such as overload protection and emergency stop allow for safe handling, while the automatic and manual lubrication systems ensure reliable, long-term operation. Its sturdy construction and base design keep it stable during heavy loads.

Comprehensive Service and Customization

Customized hopper sizes and a broad operating temperature range (-10C to 50C) make the machine adaptable to varied plant environments in India. Clients benefit from comprehensive service support, including both on-site assistance and remote troubleshooting, ensuring smooth and uninterrupted machine operation.

FAQs of Double shaft Plastic scrap crusher Machine:

Q: How is material fed into the Double Shaft Plastic Scrap Crusher Machine?

A: Material can be fed either manually or via a conveyor, depending on your workflow requirements. The hopper size is customizable to fit different material dimensions and volumes.Q: What types of plastic materials can this crusher process?

A: It is designed to handle a wide range of plastic waste, including PET bottles, plastic sheets (up to 25 at a time), and other plastic scrap, with a maximum thickness of 12 mm.Q: When should the lubrication system be used, and how is it maintained?

A: The machine features both automatic and manual lubrication options. Regular lubricationguided by the machines PLC system and operating hoursensures optimal blade and shaft performance. Maintenance schedules can be aligned to the manufacturers recommendations for best results.Q: Where can the machine be installed, and what is its mobility like?

A: Designed for stationary placement with heavy base feet, the crusher should be installed on a solid, level surface in industrial settings such as recycling plants or manufacturing units. It is not meant for frequent relocation.Q: What is the process for adjusting the output size of shredded plastic?

A: The output size can be adjusted between 20 mm and 80 mm by configuring the machines settings via its PLC control panel, allowing precise tailoring to processing or recycling requirements.Q: How does the machine ensure safe operation during use?

A: Safety is ensured with built-in features such as emergency stop buttons, overload protection, and a PLC-controlled system that monitors operation. These safeguards help prevent accidents and equipment damage.Q: What are the key benefits of using this machine for plastic scrap processing?

A: Key advantages include high processing capacity (up to 1,000 kg/h), adjustable output size, durable construction, low operational noise ( 80 dB), and reliable after-sales service. Its automation features reduce manual intervention and increase operational safety and productivity.

Price 200000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Shredder Category

single shaft shredder for plastic pyrolisis process

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380 V

Processing Type : Single Shaft Shredding

Motor Power : 37 kW

Control System : PLC based

Polythene Waste Shredder for Recycling industry

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380 V

Processing Type : Shredding

Motor Power : 10 HP

Control System : PLC Controlled

single Shaft PET Film Shredder Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 440 Volt (v)

Processing Type : Single Shaft

Motor Power : 25 Horsepower (HP)

Control System : Yes

recycling plastic bottles Shredder Machine

Price 300000 INR / Piece

Minimum Order Quantity : 10 Pieces

Voltage : 440 Volt (v)

Processing Type : Double Shaft

Motor Power : 10 Horsepower (HP)

Control System : Yes

GST : 27ABKCS4515J1Z1

Send Inquiry

Send Inquiry Send SMS

Send SMS