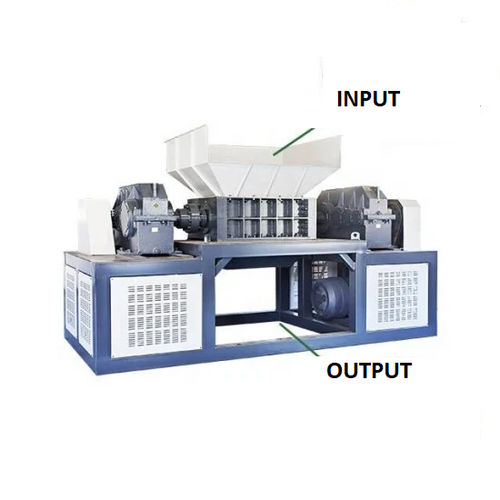

Aluminium UBC Scrap Bale Shredder Machine

Aluminium UBC Scrap Bale Shredder Machine Specification

- Weight

- Approx 3500 kg

- Size

- 3200 x 1650 x 2500 mm

- Thickness

- Upto 5 mm

- Noise Level

- Less than 80 dB

- Color

- Blue & Yellow

- Motor Power

- 75 HP

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Processing Type

- Shredding

- Material

- Mild Steel

- Application

- Aluminium UBC Can Bale Shredding

- Frequency

- 50 Hz

- Sheet Capacity

- 30-40 kg per sheet

- Capacity

- 500-2000 kg/hr

- Voltage

- 415 V

- Maintenance

- Low Maintenance Design

- Blade Material

- High Carbon Alloy Steel

- Feeding System

- Hydraulic or Conveyor

- Ideal Scrap Form

- Baled/Compacted Aluminium UBC Cans

- Cutter Speed

- 12-18 rpm

- Lubrication System

- Automatic Lubrication

- Operation Mode

- Continuous

- Shredding Chamber Size

- 1200 x 900 mm

- Safety Features

- Emergency Stop, Overload Protection

- Discharge Type

- Automatic Output Conveyor

- Power Source

- Electric

- Installation Type

- Floor Mounted

Aluminium UBC Scrap Bale Shredder Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box

- Certifications

- CE

About Aluminium UBC Scrap Bale Shredder Machine

SHREDALL Aluminium UBC Scrap Bale Shredder Machine is a powerful and efficient solution for recycling industries worldwide. This machine is specifically designed to shred, crush, and recycle used beverage cans (UBC) and other aluminium scrap into a bale.We are Manufacturer of Shredder Machine, You Get High Quality and Unbeatable Price All Over India and World Wide. By recycling aluminum, we reduce the need for mining, thus protecting our natural resources and reducing carbon emissions.

The Working of Aluminium UBC Scrap Bale Shredder Machine

The Aluminium UBC Scrap Bale Shredder Machine shreds whole bales of aluminium UBC scrap into small pieces. These pieces are then separated to remove any unwanted materials. The result is a pile of shredded aluminium, ready for further recycling processes. This machine is efficient, versatile, and contributes to environmental sustainability. Always follow the manufacturers instructions for safe operation.

Key Features

-

Robust Design: Built to withstand heavy-duty operations, ensuring long-term performance and durability.

-

High-Capacity Processing: Capable of handling large volumes of scrap, maximizing productivity.

-

Safety Measures: Equipped with safety features to protect operators and the machine itself.

Shredding Material

The shredding material in an Aluminium UBC Scrap Bale Shredder Machine is primarily used beverage cans (UBC) and other aluminium scrap.

Shredding Machine Type

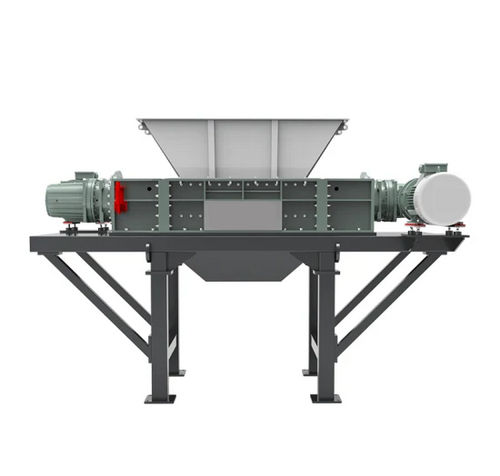

SHREDALL heavy-duty industrial primary Aluminium UBC Scrap shredders are double shaft shredders. These machines feature two rotating shafts with cutting blades that work together to efficiently shred Aluminium.

Usage/Application

The SHREDALL Dual Shaft Aluminium UBC Scrap Bale Shredder Machine is primarily used in recycling industries for processing aluminium UBC scrap and other aluminium waste.

Capacity

With a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is Automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The SHREDALL Dual Shaft Aluminium UBC Scrap Bale Shredder Machine excels in performance and is easy to install. It efficiently processes large volumes of aluminium scrap, separates aluminium accurately, and is designed with safety in mind. For installation, it features a user-friendly interface. Always follow the manufacturers instructions for safe operation.

Product Description

The SHREDALL Dual Shaft Aluminium UBC Scrap Bale Shredder Machine is a high-performance recycling tool. Its designed to process aluminium UBC scrap and other aluminium waste efficiently. The machine features a dual-shaft design for effective shredding, advanced sorting technology for precise material separation, and a user-friendly interface for easy operation. Safety features are integrated to ensure a safe working environment.

Contact Us

We are here to assist you. Feel free to Contact Us Call / WhatsApp / Email :

-

Email: info@shredall.in

-

+91 9820020754

Conclusion

Investing in an SHREDALL Aluminium UBC Scrap Bale Shredder Machine is a smart move for any recycling business. Its high-performance capabilities, safety features, and user-friendly interface make it a valuable asset. It not only enhances the efficiency of recycling aluminium scrap but also contributes to environmental sustainability.Efficient Shredding of Aluminium UBC Can Bales

This shredder is specifically designed to handle baled or compacted aluminium UBC cans, ensuring quick and uniform processing of scrap material. Its high carbon alloy steel blades guarantee reliable and precise cutting, while the large shredding chamber accommodates substantial loads. The machine delivers consistent output, supporting industrial-scale recycling operations and maximizing resource recovery.

Advanced Safety and Automatic Controls

Equipped with emergency stop and overload protection, the shredder prioritizes operator safety. Its fully automatic PLC-based control system streamlines operation and allows real-time monitoring. Combined with automatic lubrication and low maintenance requirements, the shredder provides a user-friendly, dependable solution for long-term use in demanding manufacturing environments.

FAQ's of Aluminium UBC Scrap Bale Shredder Machine:

Q: How does the Aluminium UBC Scrap Bale Shredder process aluminium can bales?

A: The machine uses high carbon alloy steel blades housed in a large shredding chamber to efficiently tear down baled or compacted aluminium UBC cans. The feeding system, either hydraulic or conveyor-based, moves the material into the chamber, where it is shredded and then discharged via an automatic output conveyor.Q: What are the safety features included in this shredder machine?

A: For operator protection, the machine is equipped with an emergency stop button and overload protection systems. These features ensure safe operation, allowing immediate halting of the machine in case of emergency and preventing damage from excessive loads.Q: When is this machine ideal to use in an industrial setup?

A: This shredder is best utilized in recycling plants, metal processing units, and industries where large volumes of baled or compacted aluminium UBC cans require efficient, continuous shredding. Its robust design and high capacity make it suitable for heavy-duty, around-the-clock operations.Q: Where should the Aluminium UBC Scrap Bale Shredder be installed?

A: This equipment is designed for floor-mounted installation in industrial settings. Ensure there is adequate space, as the machine measures approximately 3200 x 1650 x 2500 mm and weighs about 3500 kg, allowing for safe operation and easy maintenance access.Q: What benefits does the PLC-based automatic control system provide?

A: The PLC-based system streamlines machine operation, offering user-friendly controls, automation of processes, and real-time monitoring. It enhances reliability, facilitates customization of operation parameters, and minimizes the chance of human error.Q: How is maintenance handled for this machine?

A: The shredder incorporates an automatic lubrication system, which reduces manual intervention and wear on moving parts. Its design focuses on low maintenance, making routine servicing straightforward and cost-effective for operators.Q: What is the recommended power source and operational environment for this shredder?

A: This machine requires an electric power supply of 415 V, with 75 HP motor capacity and 50 Hz frequency. It should be operated in an industrial environment with sufficient voltage support and proper flooring for stable mounting.

Price 300000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Shredder Category

Double Shaft Aluminum Can Bottle Shredder Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Motor Power : 50 Horsepower (HP)

Voltage : 440 Volt (v)

Warranty : 1 Year

Capacity : 500 Kg/hr

GST : 27ABKCS4515J1Z1

Send Inquiry

Send Inquiry Send SMS

Send SMS